Fire safety in buildings is not optional — it’s essential. In the event of a fire, the ductwork that keeps air moving can quickly become a route for smoke and flames to spread. Without proper protection, these unseen pathways compromise compartmentation and put lives at risk.

This is where fire rated ductwork plays a crucial role. Designed to maintain its integrity under extreme heat, fire rated systems help contain fire within designated zones. They support overall passive fire protection strategies, slowing the spread and buying valuable time for evacuation and emergency response.

From multi-storey residential blocks to complex commercial buildings, modern regulations require systems that don’t just move air efficiently — they must also resist fire. Fire-rated ductwork is now a key part of compliance with standards such as BS 9999, EN 1366, and EN 13501.

With decades of experience in sheet metal duct fabrication and HVAC safety solutions, Doby Verrolec helps contractors and specifiers meet these demands with confidence.

Fire rated ductwork is a specially designed ventilation system built to withstand high temperatures during a fire. Unlike standard ducting, it maintains its structural integrity and function for a set time. Offten 30, 60, or 120 minutes — under fire conditions.

Standard ductwork is typically made from galvanised steel and is not built to resist fire. In contrast, fire rated systems use robust sheet metal combined with fire-resistant insulation or protective casings. These ducts are tested under strict conditions to meet fire resistance standards like EN 1366 and are rated according to EN 13501 classifications.

The main purpose of fire rated ductwork is to contain fire and smoke within designated compartments. It prevents the spread of hazardous fumes through ventilation routes and helps maintain escape paths and pressurisation systems.

Common applications include high-risk environments such as commercial kitchens, escape routes in high-rise buildings, underground car parks, and plant rooms. In each case, the duct system must support passive fire protection and meet strict building safety codes. We provide compliant, efficient HVAC accessories, duct stiffeners, duct access doors and more to ensure your systems are up to code.

Fire rated ductwork plays a vital role in passive fire protection. It helps contain fire and smoke within specific building zones, supporting compartmentation and giving occupants time to evacuate safely. In high-risk environments, such as hospitals, airports or multi-storey housing, this containment is essential to reduce harm and disruption.

Without fire rated ductwork, ventilation systems can quickly become a pathway for flames, hot gases, and smoke to travel between rooms, floors, or compartments. This can lead to rapid fire spread, blocked escape routes, and catastrophic damage to both people and property.

Installing compliant fire rated ducting helps mitigate these risks. It also ensures adherence to key UK regulations such as BS 9999, Approved Document B, and EN 1366 standards. Many insurance providers now require certified fire rated ductwork as part of commercial cover.

In a 2020 BRE report on fire safety, inadequate compartmentation — often due to non-rated duct penetrations — was a factor in several major incidents. These failures underline the need for robust, tested duct systems.

Fire rated ductwork is not just a safety feature. It’s a legal and moral obligation for building owners and specifiers alike.

Fire rated ductwork must meet strict standards to ensure it performs under fire conditions. These standards help specifiers, contractors, and building managers choose compliant systems that support safe design.

EN 1366-1 and EN 1366-8 are the primary European standards for testing fire resistance in ventilation and smoke extraction ducts. These tests simulate real fire scenarios to assess a duct’s ability to maintain integrity and insulation over time.

BS 476 Part 24 is a British Standard covering fire resistance of ventilation ducts. Though gradually replaced by EN standards in new builds, it still applies in some refurbishments or older specifications.

Both sets of standards classify ducts by their fire resistance duration, typically in minutes (e.g. E60, EI120).

Compliance with local building codes, such as Approved Document B in England, is a legal requirement. Ductwork that does not meet performance standards may fail under fire, risking building safety and breaching regulations.

Third-party certifications, such as CE marking or IFC Certification, verify that products have passed rigorous testing and provide assurance of performance on site.

Fire rated ductwork is not a one-size-fits-all solution. Different systems are designed for specific functions within a building’s HVAC network. Understanding these types helps specifiers choose the right product for each application.

These ducts are used for general air supply and extract systems. Fire rated ventilation ducts are designed to maintain airflow during normal operation, while containing fire and smoke if an incident occurs.

Typical uses: riser shafts, ceiling voids, corridor extracts.

Key considerations: insulation performance, low air leakage, and EI classification (e.g. EI60 or EI120).

Smoke extract ducts must withstand high temperatures while maintaining their structural integrity to remove smoke during a fire. They’re often required to remain operational for longer periods under extreme conditions.

Typical uses: car parks, shopping centres, escape routes.

Key considerations: tested to EN 1366-8, high integrity and pressure resistance, fire-resisting support systems.

Kitchen extract systems handle grease-laden air, which poses a higher fire risk. These ducts must prevent flame spread and be easy to clean.

Typical uses: commercial kitchens, food courts, school cafeterias.

Key considerations: constructed from galvanised or stainless steel, high-temperature insulation, access doors for cleaning and maintenance.

Fire rated ductwork relies on more than just the duct material. Supporting components and accessories play a vital role in maintaining fire integrity and system performance.

Fire dampers are installed where ductwork passes through fire-rated walls or floors. In the event of a fire, they automatically close to prevent flames and smoke from spreading. They are crucial in maintaining compartmentalisation within buildings. For more on how they work and where to install them, read Doby Verrolec’s fire damper guide.

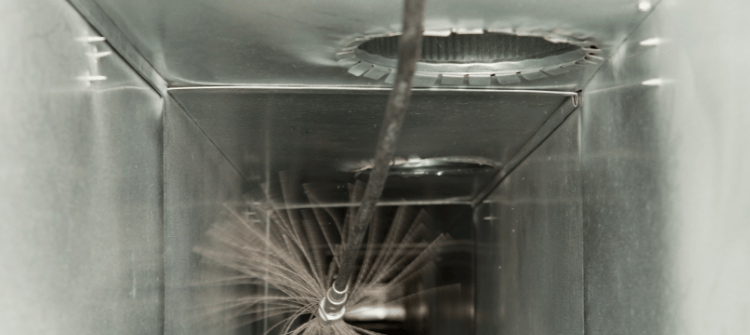

Access doors allow for inspection, cleaning, and maintenance of fire rated ductwork. Without them, dampers and other internal components can become neglected, reducing safety. Doby Verrolec offers a robust range of duct access doors designed to support long-term maintainability.

Specialist fire-resistant insulation prevents heat transfer through duct walls. It helps maintain temperature stability and protects adjacent building elements. Compatible insulation must meet the fire rating of the duct system.

Correct support is essential to maintaining duct shape during high temperatures. Doby Verrolec supplies duct stiffeners, channel profiles, and rectangular duct profiles and corners to provide reliable structural support.

Every component in a fire rated system must be compatible, tested, and certified as a full assembly. Doby Verrolec ensures this by offering a full range of HVAC accessories engineered to work together for fire integrity and airflow performance.

The fire rated ductwork sector is evolving fast. As fire regulations tighten and buildings grow more complex, manufacturers are responding with smarter, safer, and more sustainable solutions.

Recent years have seen a shift towards lighter, more durable materials that retain fire resistance. Some systems now use composite linings or improved galvanised coatings. These offer greater thermal stability without increasing weight or cost. New fabrication methods also reduce onsite cutting and waste, improving consistency and speed during installation.

Modern fire rated ductwork systems often include pre-engineered features such as integrated brackets, slide-fit profiles, or modular assembly options. These reduce installation time and human error. Systems designed with maintainability in mind—such as those with built-in access—also support easier compliance over the duct’s lifespan.

Energy efficiency is no longer separate from fire safety. Well-designed fire rated systems now help reduce pressure losses and improve airflow control. This supports both sustainability goals and long-term operational cost savings.

Doby Verrolec continues to drive innovation across its fire rated ductwork solutions. From bespoke engineering services to advanced HVAC accessories, the company supports the industry's shift towards safer, more efficient, and easier-to-install duct systems.

Correct installation and ongoing maintenance of fire rated ductwork are essential to ensure long-term performance and compliance. Even the best materials won’t deliver protection if they’re installed poorly or not maintained.

All fire rated ductwork must be installed according to the manufacturer’s guidelines and the relevant standards, including EN 1366-1. Installers must ensure all joints, penetrations, and supports meet fire resistance ratings. Use only certified sealants, fixings, and insulation materials. Where ductwork passes through walls or floors, fire stopping is critical.

Every system should be accessible for future inspection. This means integrating appropriate duct access doors at key points. Installers should also avoid damaging protective coatings or insulation during handling.

Doby Verrolec offers brackets and support systems designed to support compliant and secure installations.

Frequent issues include poor alignment, insufficient sealing, or incorrect hanger spacing. These can lead to air leaks or non-compliance. Installers should double-check measurements and fixings during setup. Access for testing and maintenance should never be an afterthought.

Training plays a vital role. Installers familiar with fire rated systems are less likely to make critical errors. Always use qualified professionals with experience in fire safety installations.

Fire rated ductwork requires routine inspection to stay compliant. Under BS 9999, systems should be checked annually or more frequently in high-risk settings. Visual inspections should look for signs of damage, corrosion, or tampering. Fire dampers must be tested for movement and reset capability.

Neglected systems can fail during a fire, endangering lives and invalidating insurance. Keeping up with scheduled checks helps prevent costly failures and regulatory breaches.

Doby Verrolec’s easy-access duct components and fixings make maintenance simpler and more reliable.

Fire rated ductwork prevents the rapid spread of fire and smoke through ventilation systems, helping to protect escape routes, reduce fire damage, and save lives. It forms a vital part of passive fire protection and building safety compliance.

In the UK, the main standards for fire rated ductwork are BS 476 Part 24 and EN 1366-1. These standards assess the duct’s ability to maintain fire resistance and smoke containment during a fire.

Fire rated ductwork is typically used in areas that require smoke extraction or protected escape routes, such as commercial kitchens, lobbies, car parks, stairwells, hospitals, and high-rise buildings.

Fire rated ductwork resists fire spread along the length of a ventilation system, while fire dampers are installed inside ducts to block fire at specific points. Both work together to improve fire safety in HVAC systems.

Yes. Insulated fire rated ductwork helps maintain fire resistance by protecting against heat transfer. The insulation type depends on the duct’s application, such as kitchen extract or smoke control.

Fire rated ductwork should be inspected annually, with full performance checks every 3–5 years depending on usage and environment. Regular inspection ensures continued compliance and safety.

Yes. Fire rated ductwork can be retrofitted into existing buildings, provided it meets current standards and is installed by certified professionals. Retrofit solutions help upgrade older HVAC systems to modern fire safety requirements.

Fire rated ductwork is tested under high-temperature conditions in accordance with EN 1366-1 or BS 476 Part 24. Tests assess integrity, insulation, and pressure performance during fire exposure.

Fire rated ductwork is a critical part of any passive fire protection strategy. It stops fire and smoke spreading through a building’s ventilation system, protecting people and property.

To be effective, fire rated ductwork must be properly designed, correctly installed, and regularly maintained. This isn’t just best practice—it’s required by law. Failure to comply can lead to serious safety risks and regulatory penalties.

Whether you’re working on a new build or upgrading an existing system, choosing the right products and partners makes all the difference. With decades of experience, Doby Verrolec provides trusted solutions that meet stringent fire safety standards.

Explore Doby Verrolec’s full range of fire rated ductwork products or get in touch for tailored advice on compliant system design and specification.

© Copyright 2026 Doby Cleats Limited. Privacy Policy