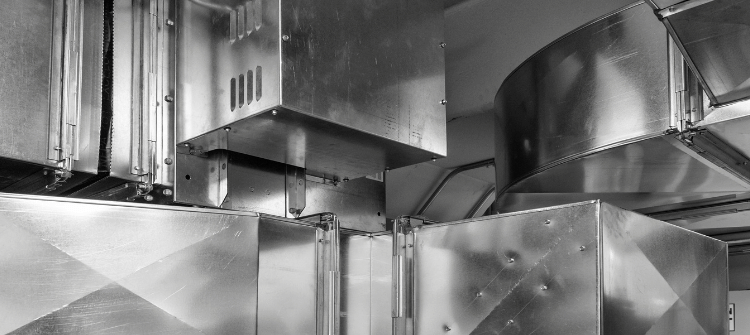

Ductwork is a vital part of any building’s HVAC system. It distributes air for heating, ventilation, and cooling. But it can also act as a hidden route for fire and smoke if left unprotected.

Fire dampers in ductwork are essential to passive fire protection. These small but powerful devices help contain fire and smoke within compartments, slowing down their spread. Without proper containment, a fire can travel rapidly through duct runs, bypassing fire-rated walls and ceilings designed to stop it.

In commercial and multi-occupancy buildings, unprotected ductwork poses serious safety risks. Corridor penetrations, riser shafts, and ceiling voids can allow flames to spread across multiple floors in minutes. Fire services, insurers, and building control teams all demand proper ductwork fire protection to mitigate this risk.

This post explores how to safeguard duct systems using fire dampers, looking at:

With over 50 years in the industry, Doby Verrolec is a trusted UK manufacturer of high-performance ducting components and access solutions. Their commitment to safety, innovation, and buildability helps contractors and specifiers meet the highest fire safety standards with confidence.

A fire damper in ductwork is a passive fire protection device. Its job is simple but critical: stop fire and smoke from spreading through the HVAC duct system.

Ducts pass through fire-rated walls, ceilings, and floors. This creates a potential breach in the building’s fire compartmentation. Fire dampers are installed at these junctions. In the event of a fire, they close automatically to block the path of heat, smoke, and flames.

There are two common activation methods:

Once closed, the damper forms a physical barrier within the duct, containing the fire in one compartment. This gives occupants more time to escape and emergency teams more time to respond.

Fire dampers ductwork configurations vary by system. Dampers are fitted where ductwork crosses fire-rated barriers. They must be installed in a way that ensures both airflow performance and fire protection. Often, they’re used in:

Fire dampers are not standalone. They work as part of a wider strategy that includes fire-rated duct systems, insulation, sealing compounds, channel profiles and access panels for maintenance.

Choosing the right damper type, installing it correctly, and maintaining it over time are essential to meeting UK fire safety laws and keeping building occupants safe.

In any building, ductwork connects multiple rooms, floors, and zones. Without protection, it can act as a channel for smoke, heat, and flames. This puts lives at risk and compromises the building’s integrity. That’s why installing a fire damper for ductwork is a legal and practical necessity in most commercial and residential settings.

HVAC duct systems are designed to move air efficiently. But in a fire, these same ducts can spread smoke quickly from one compartment to another. Smoke inhalation is the leading cause of death in fires, and rapid smoke movement reduces escape time.

A fire damper for ductwork works by shutting off the airflow where the duct passes through a fire-rated wall, floor, or ceiling. This helps maintain the fire compartmentation strategy, a core element of passive fire protection.

Fire dampers are not optional where ducts pass through protected barriers. In the UK, they are required by:

These standards outline where and how dampers must be installed, tested, and maintained. Compliance is mandatory for Building Control approval.

Failing to meet these requirements can lead to:

There are several typical locations where dampers must be fitted to protect HVAC fire safety:

Fire dampers support wider passive fire protection strategies. They help isolate zones, slow fire progression, and maintain structural integrity. But they must be installed as part of a certified, well-designed system – not as a box-ticking exercise.

Doby Verrolec supports compliance through a range of fire-rated duct systems, fixings, duct stiffeners and access components. These help ensure your project not only meets standards but performs reliably in a real-world emergency.

Choosing the right fire damper is essential for protecting ducted HVAC systems and ensuring compliance with fire safety regulations. Different types of ductwork fire dampers are designed for specific applications, depending on airflow, location, and building type. Below are the main categories used in the UK market.

Curtain fire dampers are the most widely used type in commercial and residential buildings. They feature a folded metal curtain held open by a fusible link. When the temperature exceeds a certain threshold—typically 72°C—the link melts, causing the curtain to drop and block the duct.

Where they're used:

These are cost-effective and simple to install but must be installed in strict accordance with manufacturer guidelines to maintain integrity during fire conditions.

Intumescent fire dampers contain materials that expand when exposed to heat. This expansion seals off the duct opening without moving parts.

Where they're used:

While not as common as curtain types, intumescent dampers are valued for their silent operation and minimal maintenance needs.

Motorised fire dampers, also known as actuated dampers, are equipped with electric or thermoelectric actuators. These are triggered by a building's fire alarm or smoke detection system.

Where they're used:

Motorised dampers often serve dual roles—fire protection and airflow control—making them ideal for fire-rated duct systems with integrated smoke ventilation.

Each type of fire damper has its own advantages. The selection depends on:

For HVAC contractors, engineers, and specifiers, Doby Verrolec provides tested and certified components to suit a wide range of ducting configurations. These include compatible fixings, access panels, and fire-rated duct systems to support safe, code-compliant installations.

Correctly installing fire dampers is vital for ensuring effective passive fire protection and meeting UK building safety standards. Poor installation not only increases the risk of fire spread but also leads to failed inspections, compliance issues, and possible liability.

Below are the core practices for safe, compliant fire damper installation in ductwork systems.

Fire dampers must be installed where ductwork passes through fire-rated walls, floors, or partitions. These locations are critical points for compartmentation and fire containment.

The damper should sit flush within the barrier, and both the damper and surrounding materials must match the required fire resistance rating, typically 60, 90, or 120 minutes depending on the building type and application.

All fire dampers must be easily accessible for testing, reset, and maintenance. This is not optional—it’s required by BS 9999 and enforced by fire safety audits.

To enable this, install access doors for fire dampers as close to the unit as possible. These doors allow engineers to inspect the fusible link, clear debris, and ensure the damper closes properly. Doby Verrolec offers a wide range of access panels and inspection doors specifically designed for this purpose.

The gap between the damper and the surrounding wall or floor should be sealed using tested, certified fire-stopping materials. These include intumescent mastic, fire pillows, or specialist sealants depending on the application.

Fire-stopping helps ensure that smoke and flames cannot bypass the damper through unsealed joints, preserving the integrity of the fire containment ductwork.

Always follow the specific manufacturer’s installation guide. This includes direction of airflow, damper orientation, and fixing instructions. In addition, adhere to HVCA DW145, which provides detailed industry-approved guidance on fire damper installation and maintenance.

A fire damper must be independently supported and aligned with surrounding ductwork. Relying on adjacent ducting for structural support is a common installation error. Doby Verrolec supplies duct hardware and support systems to ensure correct and secure mounting.

By working with trusted suppliers like Doby Verrolec, installers can access fully compatible, tested systems for fire damper ductwork installation. Our components are designed to help engineers meet fire safety regulations without unnecessary complexity or compromise.

Maintaining a fire damper in ductwork is just as important as installing it correctly. Without regular testing and maintenance, even the best-designed fire damper may fail to operate when needed—putting building occupants and assets at risk.

In the UK, BS 9999 sets out the legal expectation for the maintenance of ductwork fire dampers. It states that:

Some building types or insurers may also require more frequent checks, especially in high-risk or high-occupancy buildings.

Qualified engineers typically perform the following steps when testing a fire damper in ductwork:

Any damper that fails must be repaired or replaced immediately to remain compliant with HVAC fire safety standards.

Many maintenance issues arise not from the dampers themselves—but from poor fire damper access. If access doors are not installed or are poorly placed, engineers cannot perform testing safely or effectively.

Doby Verrolec helps address this issue with a full range of access doors for fire damper maintenance. These access panels are designed to:

We also offer compatible fixings and hinge systems that allow access doors to function reliably over time, even under demanding service conditions.

Whether you're maintaining a large commercial HVAC system or overseeing regular inspections in residential developments, fire dampers must never be overlooked. With Doby Verrolec’s support, achieving long-term compliance is both practical and cost-effective.

Even well-specified fire dampers in ductwork can become ineffective if common installation or maintenance issues are overlooked. These problems often reduce system performance and may lead to compliance failures during inspections.

Over time, dust and debris can accumulate inside ductwork and around fire dampers. This buildup may prevent the damper from closing fully in the event of a fire.

How to avoid it:

A frequent issue is poor damper placement or the absence of access panels. Without proper access, dampers cannot be tested, maintained or repaired—leading to regulatory non-compliance.

How to avoid it:

If a fire damper is not sealed correctly within a fire-rated barrier, it cannot maintain the compartmentation needed to limit fire and smoke spread.

How to avoid it:

Fusible links—used in many traditional fire dampers—can degrade over time due to heat exposure, corrosion or environmental conditions like high humidity. A faulty link means the damper may not activate.

How to avoid it:

Doby Verrolec understands the challenges faced by HVAC professionals, fire safety consultants and M&E specifiers. That’s why our fire-rated duct systems and duct hardware and support components are developed with ease of installation, long-term access and robust performance in mind.

Our components help teams:

By choosing smart solutions early in the design and installation process, you avoid costly corrections later—and ensure safer, more efficient HVAC systems.

A fire damper is a safety device installed in ductwork that automatically closes to prevent the spread of fire through ventilation systems.

Not all ducts need fire dampers, but they are required where ducts pass through fire-rated walls, floors, or partitions to maintain compartmentation.

Fire dampers should be tested at least annually according to BS 9999 to ensure they close properly and meet fire safety regulations.

Common types include curtain fire dampers, intumescent dampers, and motorised fire dampers, each suited to different system requirements.

If a fire damper fails to close, fire and smoke can spread through the ductwork, compromising building safety and breaching fire regulations.

Fire dampers in ductwork may seem like a minor part of a much larger HVAC system, but their role in passive fire protection is critical. These components form a vital barrier against the rapid spread of fire and smoke—preserving compartmentation, buying time for evacuation, and protecting life and property.

When properly specified, installed, and maintained, fire dampers help ensure full compliance with UK fire safety regulations such as BS 9999 and EN 1366-2. They support overall HVAC fire safety and contribute to the integrity of fire-rated duct systems across commercial, industrial and residential settings.

As fire protection responsibilities grow more complex, so too does the need for durable, accessible and compliant ductwork solutions. That’s why careful planning, correct component selection, and regular maintenance are essential—not just for legal compliance, but for long-term building safety.

Contact us to discover how we can help ensure you’re compliant, efficient and have the right parts for your project.

© Copyright 2026 Doby Cleats Limited. Privacy Policy